Innovating Sanitation with Seppelec

The food and drinks industry demands high-yield, energy-saving cleaning systems to achieve enhanced sustainability standards. The shift from hot to cold temperature cleaning procedures is the new paradigm, introducing a new set of chemicals, detergents, and disinfectants.

Seppelec’s Comprehensive Approach to Cleaning

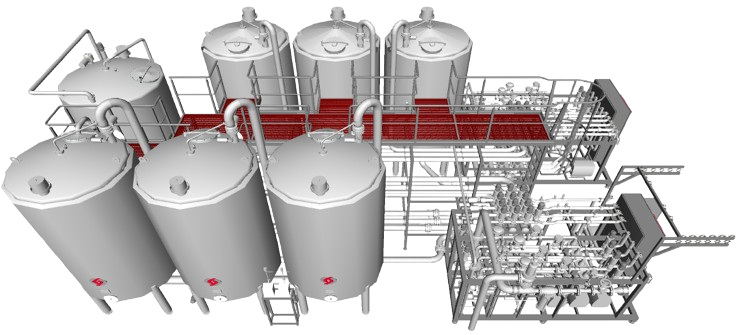

At Seppelec, we understand cleaning as a multifaceted process where the act of cleaning itself is just one part of the whole. An optimized design of the installation, along with a correct layout of the appropriate processes, determines the effectiveness and efficiency of the cleaning to the same extent as the cleaning unit itself. From this perspective, the cleaning technology must be considered holistically.

Experience and Expertise

With over 25 years in the beverage and food sector, we bring unparalleled knowledge and expertise to every project.

Innovative Solutions

Our dedication to innovation ensures that we offer the most advanced and effective technological solutions available.

Customer-Centric Approach

We work closely with our clients to understand their unique needs and provide tailored solutions that drive success.

Sustainability Focus

Our commitment to sustainability helps you achieve your environmental goals while maintaining operational efficiency.

Contact us today to learn more about how our dissolution and treatment system can benefit your operations and help you achieve your production goals.

To define a suitable installation design and Process, the following data must be disclosed:

Types of products to be produced.

Compartmentalisation of processing areas.

Desired degree of automation.

Purity and ash concentration of the raw sugar and of the simple syrup produced

Colour range of the raw sugar (max recommended 1.200 ICUMSAS)

Functional Units

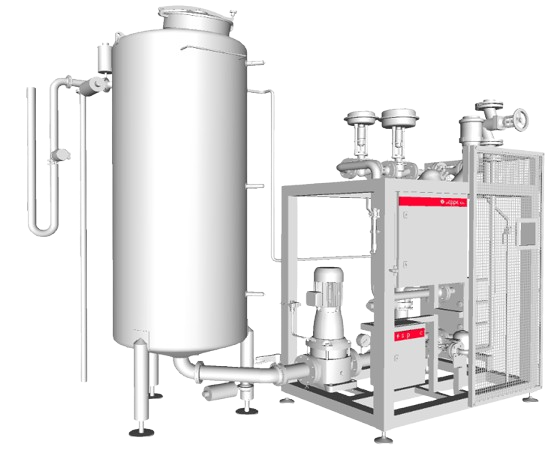

Ancillary equipment