CLEANING TECHNOLOGY

SeppelCIP® stands as a testament to years of expertise in the industry and close collaboration with cleaning agent companies. This collaborative effort has yielded a meticulously refined system that integrates all necessary components for precise cleaning control. Each element of the SeppelCIP has been carefully engineered to optimize the efficiency of cleaning processes while minimizing environmental impact.

Moreover, the SeppelCIP incorporates state-of-the-art measurement equipment and a robust global control system, enhancing reliability and operational consistency. This combination of precision instruments and comprehensive control mechanisms ensures that cleaning procedures are executed with utmost accuracy and repeatability, crucial for maintaining stringent quality standards in manufacturing environments.

Beyond its technical prowess, the SeppelCIP offers adaptable configurations to suit diverse industrial settings. Whether adjusting to different space constraints or accommodating varied production demands, the system’s flexibility allows seamless integration into existing manufacturing infrastructures. Additionally, the provision of comprehensive support and all necessary equipment ensures smooth implementation and sustained operational efficiency.

The integration of precise measurement equipment and a comprehensive system control enhances the robustness of Seppelec’s solution:

Given the range of cleaning agents and heterogeneity of equipments, Seppelec has design a high flexible solution for cleaning. SeppelCIP covers a wide range of configurations depending on the cleaning agents, cleaning needed and equipment requests:

– Cleaning flows: 5-90 m3/h

– Flow variation: 20-100%

– Cleaning agents: caustic, acid, desinfectants (clorine or PAA) and water.

– Lines: 1-6

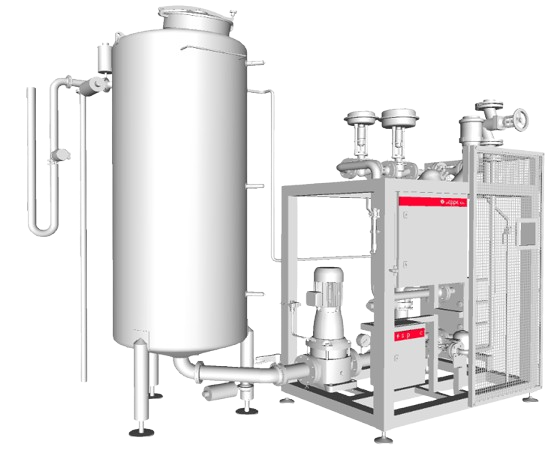

– Aditional modules can be added:

Chemical storage and dosings

Desgastins tank

Return modules

Differents configurations:

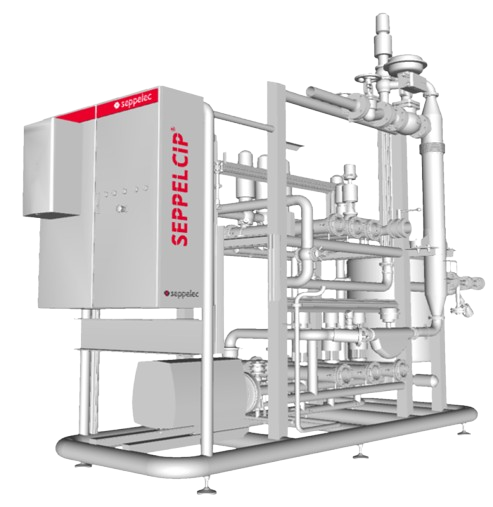

SEPPELCIP

Standard version

SEPPELCIP

Compact

SEPPELCIP

Mobile

* Other desings can be manufactured upon request