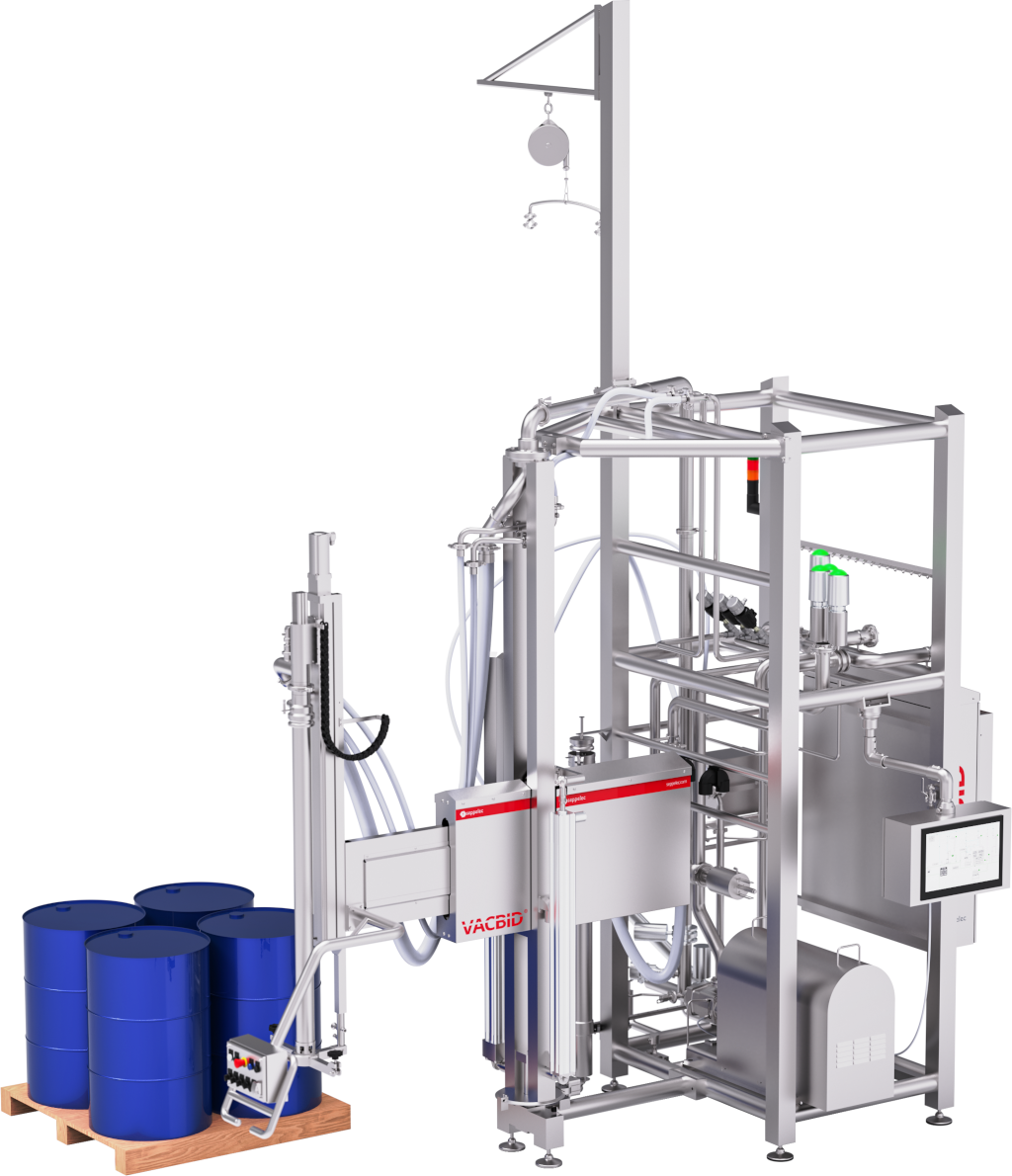

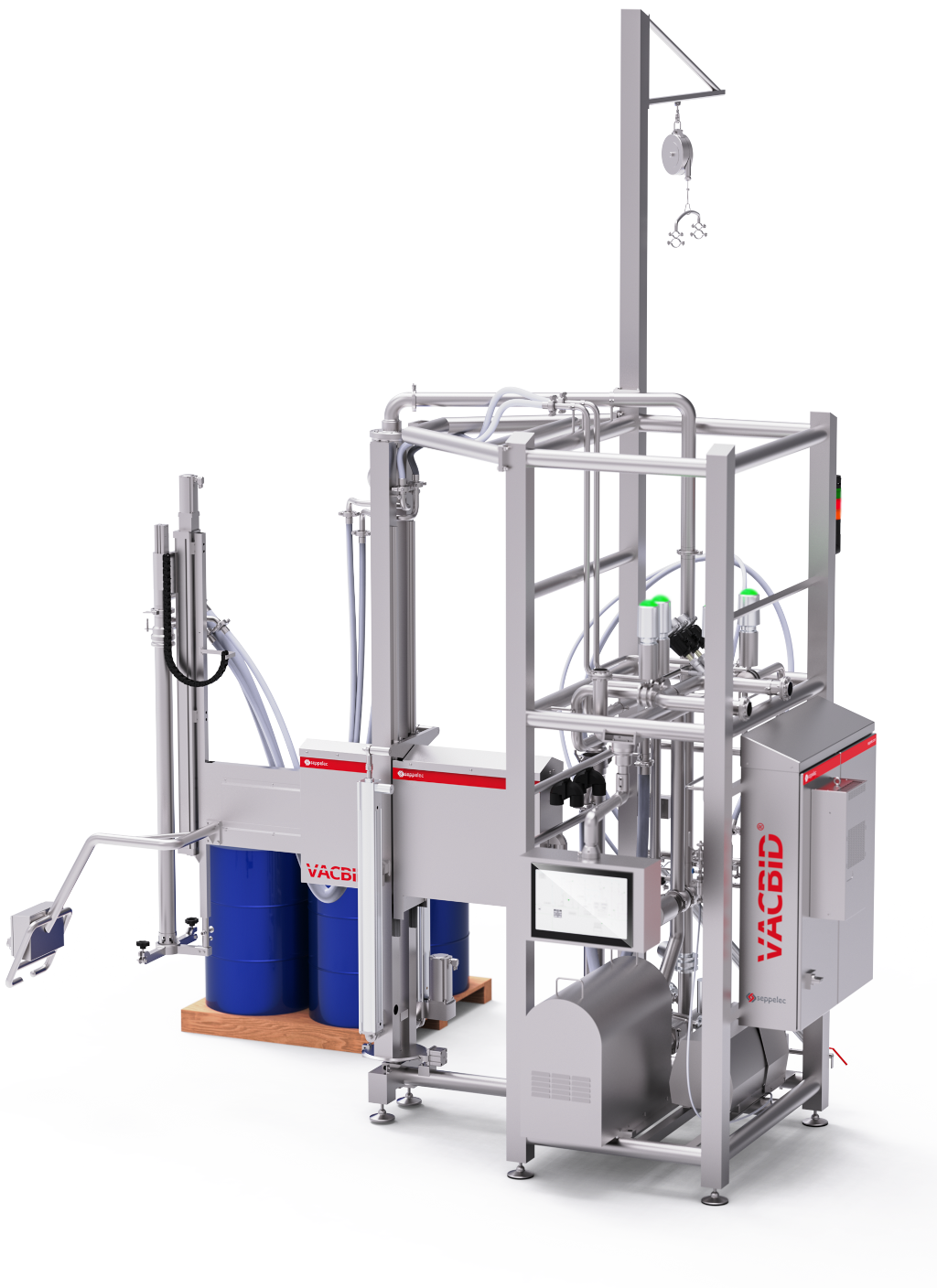

Emptying System

AUTOMATIC EMPTYING SYSTEM FOR PULPS & CONCENTRATES

Vacbid® is the ideal equipment for emptying high-viscosity products, suitable for the production of juices, soft drinks, or any product that requires quick and efficient emptying with minimal operator intervention.

In production since 2011 and patented 10 years ago, it is the key equipment in the syrup manufacturing room and a flagship of servo-assisted operation.Its patented extraction system avoids any contact between the product and the external environment, keeping optimal hygienic conditions during the whole process.

The proper development of the equipment, combined with the incorporation of auxiliary equipment, provides the emptying system with easy and intuitive operation and additional functionalities such as weight-controlled emptying and automatic detection of the end of the drum.

Functional Unit Information Sheet: Download PDF here

The Vacbid emptying system allows for minimal operator intervention and guarantees complete and homogeneous emptying of all products.