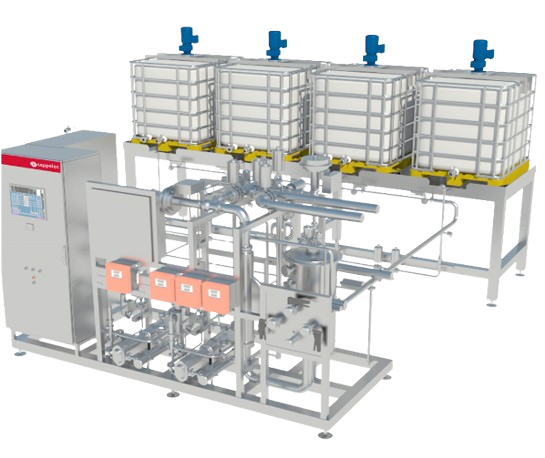

HIGH-LEVEL PERFORMANCE INLINE BLENDER

The Massmol® has been updated over the years and the available technology has allowed new forms of control to be reliably incorporated. Starting out as a unit for dosing liquid parts, the Massmol has become a worldwide benchmark in the continuous production of beverages with all kinds of ingredients.

Different formulations are available and can be combined in the same machine, giving MASSMOL® great versatility.

It is the most efficient system for formulations using large format liquid concentrates and offers great advantages over batch production.

The savings in production time, ingredient handling and CIP cleaning are extremely high. Manual dosing errors and product waste are also eliminated.

The Massmol is a high-level performance inline blender, equipped with recipes management, complete traceability, automatic cleaning and detailed control of whole process.

Thanks to the control system and the possibility of adapting its structure to the needs of the product, continuous mixing has positioned itself as the roadmap for all producers in the sector, who are looking for compact solutions and just-in-time production.

The modular configuration of the MASSMOL® enables it to adapt to the demands of the market, both present and upcoming.

The continuos inline blending solution from Seppelec, Massmol, covers a wide range of configurations depending on the customer demand:

– Production flows: 5-35m3/h

– Flow variation: 25-100%

– Products: juice, syrup and final beverage

– Streams: 2-6

– Aditional modules can be added:

IBC stations

Pre-dissolving station

Buffer tank

Desaireation water tank

Examples:

MASSMOL® CC

for regular cola drink

MASSMOL® CZ

for sugar free cola drink

MASSMOL® SM

for sucralose dissolution

MASSMOL® LS

for low sugar cola drink

* Other desings can be manufactured upon request