Ensuring Excellence with Seppelec

Water is a core element in the production of soft drinks and energy drinks, making up an average of 80% of the formulation recipes. As such, ensuring its flavor, optimization, and safety is essential in the treatment processes, which require highly efficient functional units.

Seppelec’s Expertise and Innovation

At Seppelec, we combine our extensive expertise in water-based products with deep technical knowledge of water’s chemical composition. This synergy has allowed us to develop a new range of functional units that meet the market’s challenges head-on. Our innovations in water treatment offer key improvements in efficiency, automation, and hygiene, ensuring the highest standards in your production processes.

Experience and Expertise

With over 25 years in the beverage and food sector, we bring unparalleled knowledge and expertise to every project.

Innovative Solutions

Our dedication to innovation ensures that we offer the most advanced and effective technological solutions available.

Customer-Centric Approach

We work closely with our clients to understand their unique needs and provide tailored solutions that drive success.

Sustainability Focus

Our commitment to sustainability helps you achieve your environmental goals while maintaining operational efficiency.

At Seppelec, we are committed to continuous innovation and excellence. Our technical achievement in the dissolution and treatment system represents our dedication to advancing beverage production technology. By choosing Seppelec, you are investing in a solution that not only enhances the quality of your product but also contributes to sustainable and efficient production practices.

Contact us today to learn more about how our dissolution and treatment system can benefit your operations and help you achieve your production goals.

To define a suitable installation design and Process, the following data must be disclosed:

Available water full components analysis and quality standard demanded.

Level of Automation required.

Distribution system preferred.

Purity and ash concentration of the raw sugar and of the simple syrup produced

Colour range of the raw sugar (max recommended 1.200 ICUMSAS)

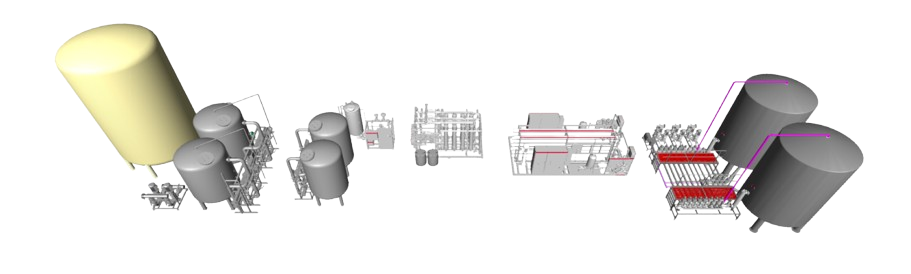

Functional Units

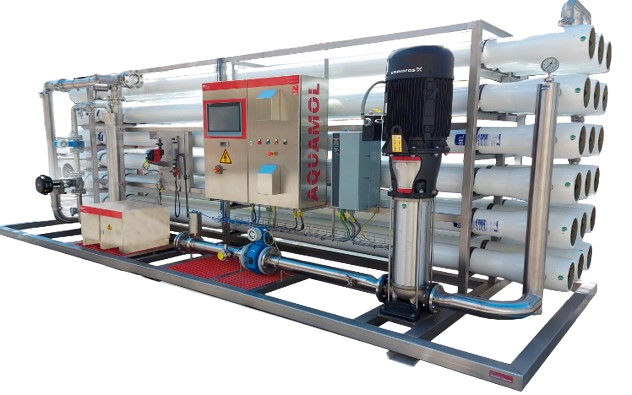

Our complete water process is commercialized under the functional unit “AQUAMOL”, which embeds distinctive units:

Ancillary equipment