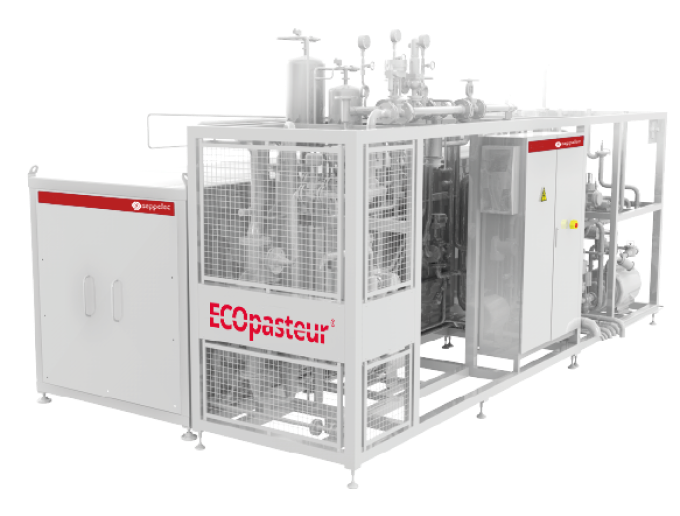

Pasteurization System

THERMAL TREATMENT UNIT WITH MULTIFUNCTIONAL DESIGN

The EcoPasteur is Seppelec’s technical solution for thermal pasteurization and sterilization processes in beverages. The selection of thermal profiles and heat exchange equipment allows the system to extend operational uptime and reduce cleaning requirements.

The control system and self-cleaning functionality enable operators to easily switch between recipes and adapt equipment operation to production rhythms. The multiproduct equipment supplied covers a wide range of applications, facilitating easy expansion of our clients’ portfolios without necessitating changes to existing equipment.

EcoPasteur is suitable for variable products, capacities and operating conditions:

– Syrups

– Non-carbonated drinks-

– Juice and nectar, products with pulps and fibers

– Milk

– Soups and sauces

The EcoPasteur pasteurization equipment integrates highly reliable elements to prevent cross-contamination during processes and maintains precise control over critical variables:

Given the range of products and temperature profiles, Seppelec has selected the most suitable technology for each solution. The thermal treatment solution from Seppelec, EcoPasteur, covers a wide range of configurations depending on product characteristics:

– Production flow: 5-40 m3/h

– Pasteurization types: HTST, UHT, Hot Fill

– Product viscosity: 1-1.000 cP

– Aditional modules can be added:

Homogenizer

Recovery tank

Milk skimming machine

Differents available technologies:

PLATES ECOPASTEUR®

ideal for dairy products

TUBULAR ECOPASTEUR®

ideal for juices with particules