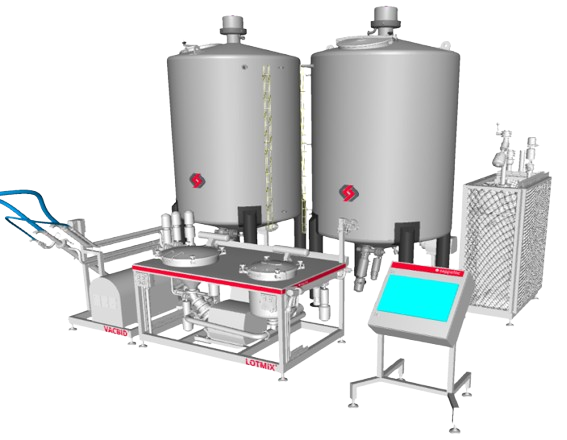

Mixing System

BLENDING UNIT FOR SOLID AND LIQUID INGREDIENTS

The Lotmix® is the evolution of traditional mixing equipment, presented as a multifunctional unit that not only dissolves solid ingredients but also integrates liquid ingredients and manages the entire product manufacturing process.

The composition of the equipment varies depending on the ingredients to be integrated into the beverage, ranging from its simplest form as a batch mixing unit to its most comprehensive form as a complete formulation unit equipped with storage tanks. It is the versatility of its use and level of configuration that makes the Lotmix® equipment stand out from market competitors.

Functional Unit Information Sheet: Download PDF here

The Lotmix system allows maximum adaptation of the equipment to each ingredient, resulting in significant savings in handling difficult-to-dissolve ingredients.

The batch dissolving solution for solids and liquids ingredients from Seppelec, Lotmix, covers a wide range of configurations depending on the recipes:

– Production flows: 5-20m3/h

– Products: dairy, isotonic, energy drinks, juice and carbonated soft drinks

– Range of ingredients packaging:

Solids: BigBag and bags

Liquids: Jerrycan and bottles

– Available technologyes: high-shear mixer for direct dissolution

– Aditional modules can be added:

Vacbid for managing pulps and concentrates in large packaging

Heater and cooler

Pre-batch tanks

Homogeneizer

Handling devices: slizer table, hoist & lifter

– ATEX version available.

Examples:

LOTMIX® HC – for bigbag

LOTMIX® S – for bags and bottles

* Other desings can be manufactured upon request