Embracing the Future with Seppelec

Changing consumption trends, rising energy costs, and increasing restrictions on waste production are driving a significant technological transition towards efficiency and sustainability in the soft drink industry. At the same time, stricter regulations affecting materials and designs demand the use of higher-performance functional units to meet these new standards.

Adapting to Market Dynamics

With more than 25 years of experience in the beverage and food sector, Seppelec is at the forefront of this transition. We offer a new and updated portfolio of advanced functional units that are perfectly suited to meet current market standards. Our technological solutions are designed to provide overall control of the processes involved, ensuring full traceability within the system and incorporating the latest developments available in our equipment, thus guaranteeing efficiency and preventing obsolescence.

Experience and Expertise

With over 25 years in the beverage and food sector, we bring unparalleled knowledge and expertise to every project.

Innovative Solutions

Our dedication to innovation ensures that we offer the most advanced and effective technological solutions available.

Customer-Centric Approach

We work closely with our clients to understand their unique needs and provide tailored solutions that drive success.

Sustainability Focus

Our commitment to sustainability helps you achieve your environmental goals while maintaining operational efficiency.

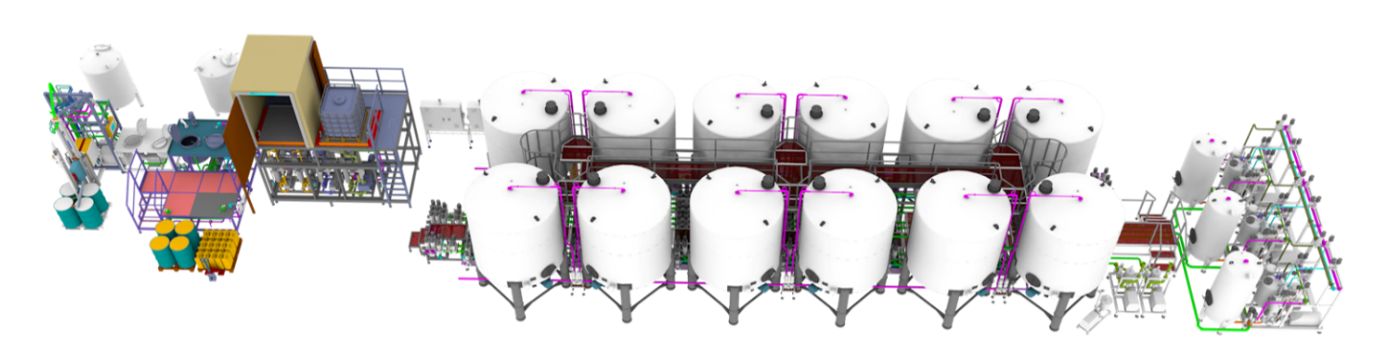

At Seppelec, we are committed to continuous innovation and excellence. Our technical achievement in the dissolution and treatment system represents our dedication to advancing beverage production technology. By choosing Seppelec, you are investing in a solution that not only enhances the quality of your product but also contributes to sustainable and efficient production practices.

Contact us today to learn more about how our dissolution and treatment system can benefit your operations and help you achieve your production goals.

To define a suitable installation design and Process, the following data must be disclosed

Types of products to be produced.

Desired degree of automation.

Bottling lines capacity

Purity and ash concentration of the raw sugar and of the simple syrup produced

Colour range of the raw sugar (max recommended 1.200 ICUMSAS)

Functional Units

Ancillary equipment