Comon situation

Problem to solve

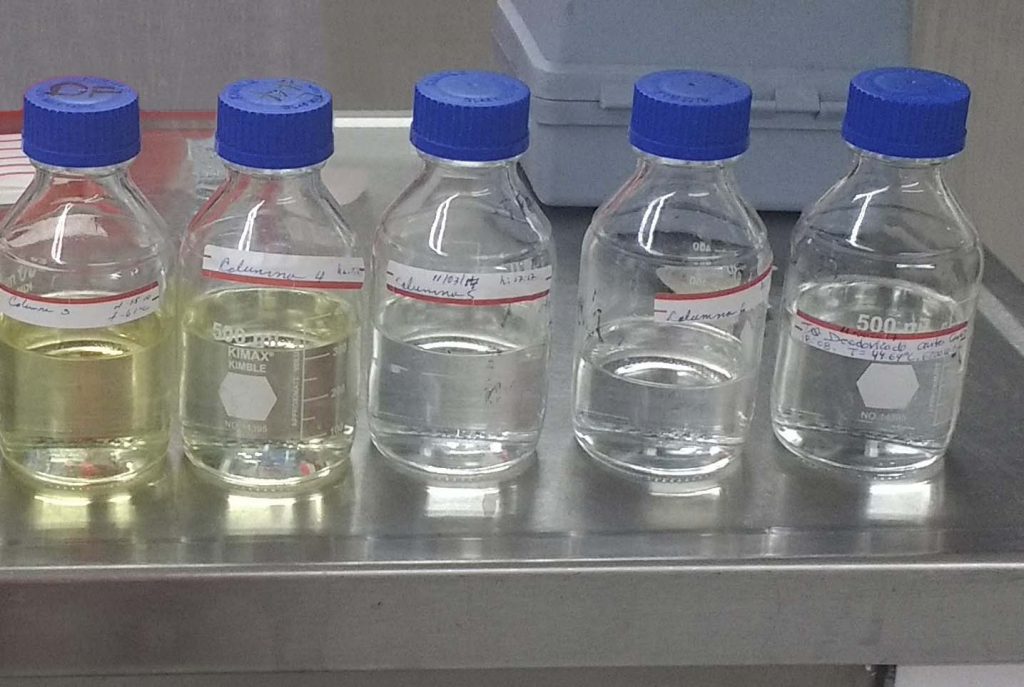

Due to the big range of sugar quality on different areas, countries and suppliers, must face up to several issues in order to comply with the beverage manufacture standards and demands, resulting in high economic costs.

- Low sugar content of starch and dextrane.

- Ionic Exchange properties depends on: color operation range & the final result.

- Ionic Exchange demineralization system for high purity or quality.

- *options: bag filters, conventional cartridges filters and/or diatomite aid filters.

Solution

Seppelec target

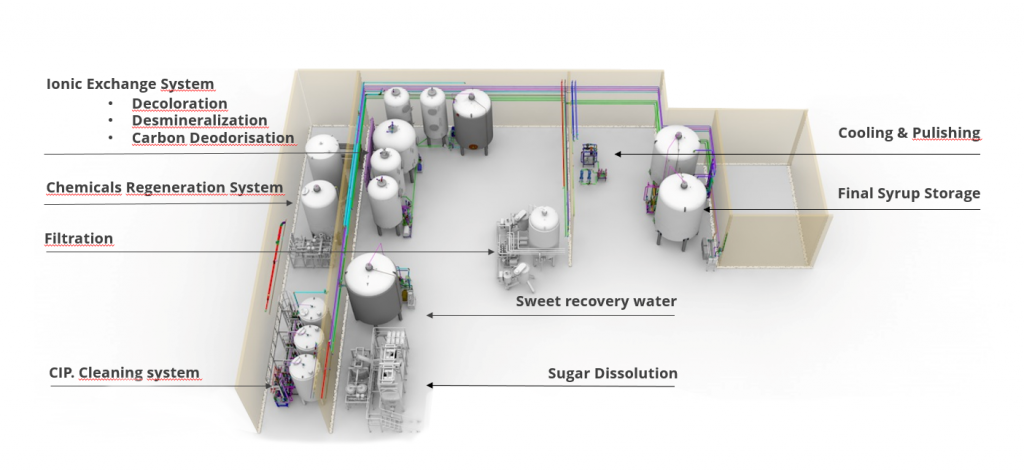

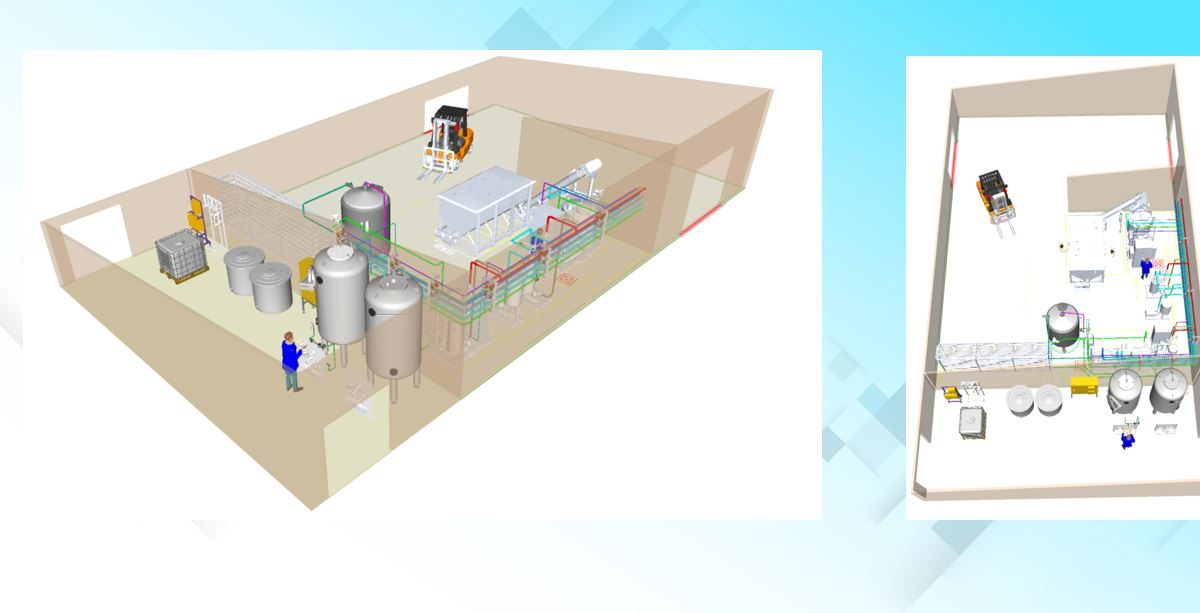

Our main goal is to achieve a high-throughput clarification system able to manage different sugar qualities and to produce a sugar syrup that complies with the beverage industries’ standards.

- Direct reducing the operating costs in energy, water and chemicals.

- System offers minimum waste and product losses.

- Fully automatic control.

- Higher flexibility in raw materials acquisition.

- Ensure the sugar availability without extra-incremental costs.

- Get a final syrup to comply the standards for beverage processing.

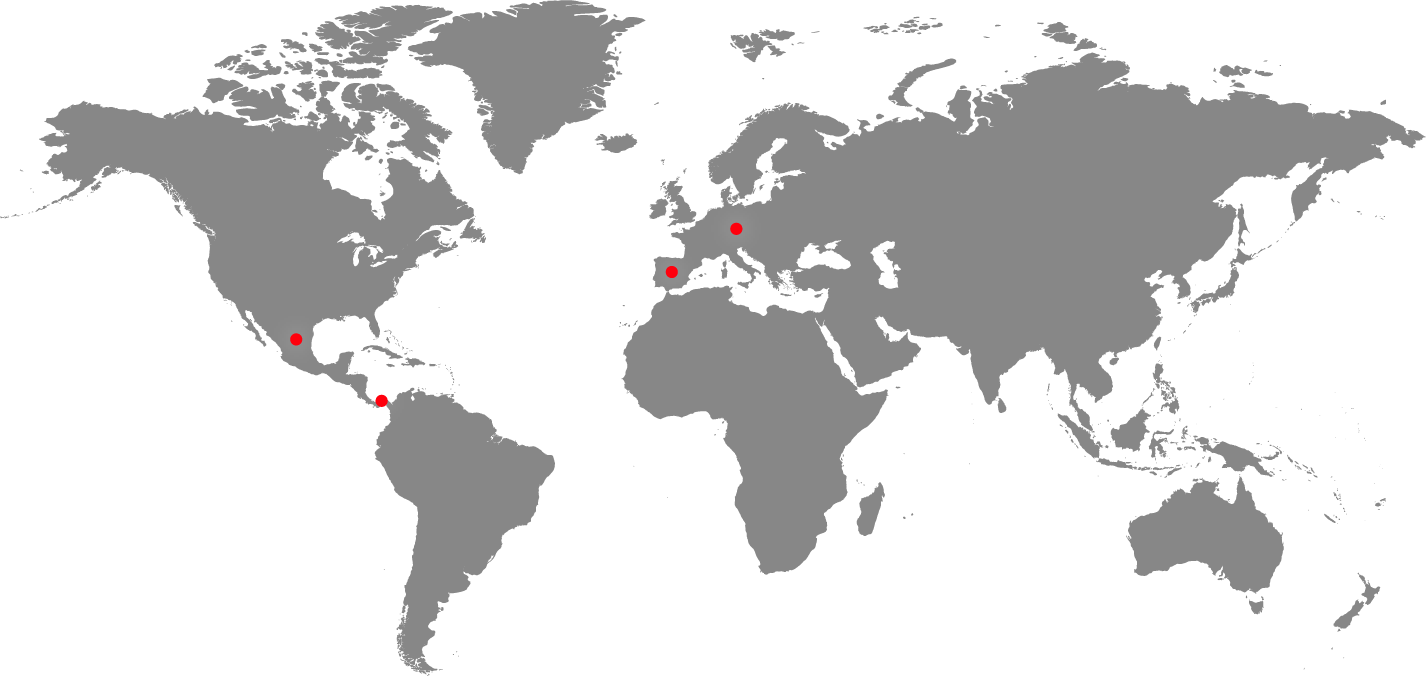

Outstanding projects

| Client: Bepensa |

| Products: Sugar treatment |

| Aplications: Sugar Clarified Rooms |

| Client: Aga bottling plant |

| Products: Sugar treatment |

| Aplications: Sugar Clarified Rooms |

| Client: East Africa Bottling Share Company |

| Products: Sugar treatment |

| Aplications: new syrup room & sugar dissolver |

| High colour sugar treatment & cip system |

| Client: Aga bottling plant |

| Products: Sugar treatment |

| Aplications: Sugar Clarified Rooms |

Sugar Clarification technology