We are pleased to announce that Van Der Molen-Seppelec Group will be present at two of the most representative fairs of the beverage sector in 2019, BrauBeviale and Drink technology India, presenting new products, services and thus strengthening its presence in the market.

The first date to consider is BrauBeviale 2019, probably the world’s most important trade fair for the beverage industry this year, which will take place from 12 to 14 November at the BrauBeviale Exhibiton Centre in Nuremberg, Germany.

In 2018 more than 40,000 trade visitors – more than 18,000 of them international – travelled to Nuremberg to discuss high-quality raw materials, advanced technologies, efficient logistics and dynamic marketing concepts.

There were 1,094 exhibitors, 53% of them international, among which were Van Der Molen and Seppelec, and where they presented their products and solutions related to the entire beverage production process chain.

You can find us in Hall 9, at Stand 9-202.

The exhibition schedule will be: Tuesday, 12 to Thursday, 14 November 2019. 09:00 – 18:00.

For more information, please visit the fair website (https://www.braubeviale.de/en).

Exactly one month later, we will travel to India to be in Drink technology India, this time based in New Delhi, the leading platform for the beverage, dairy and liquid food industry in India.

Van Der Molen-Seppelec Group will travel there to present new products, services and strengthen its presence in the Asian market.

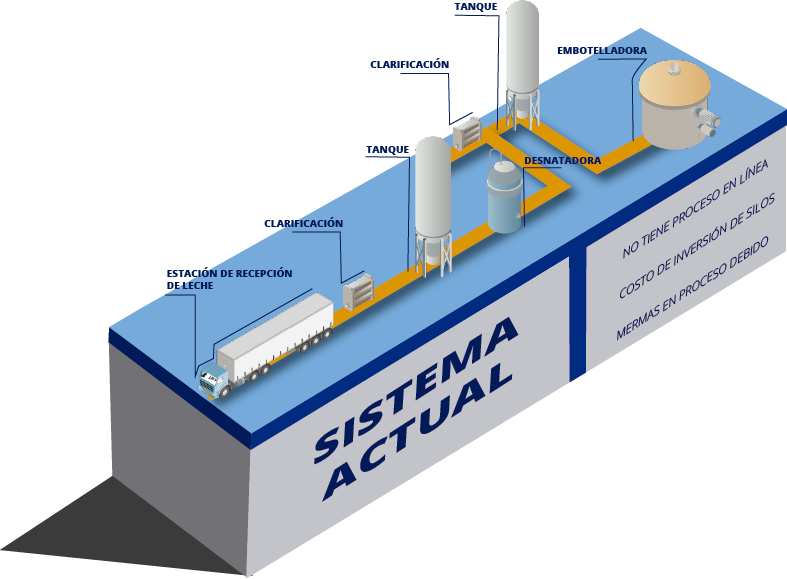

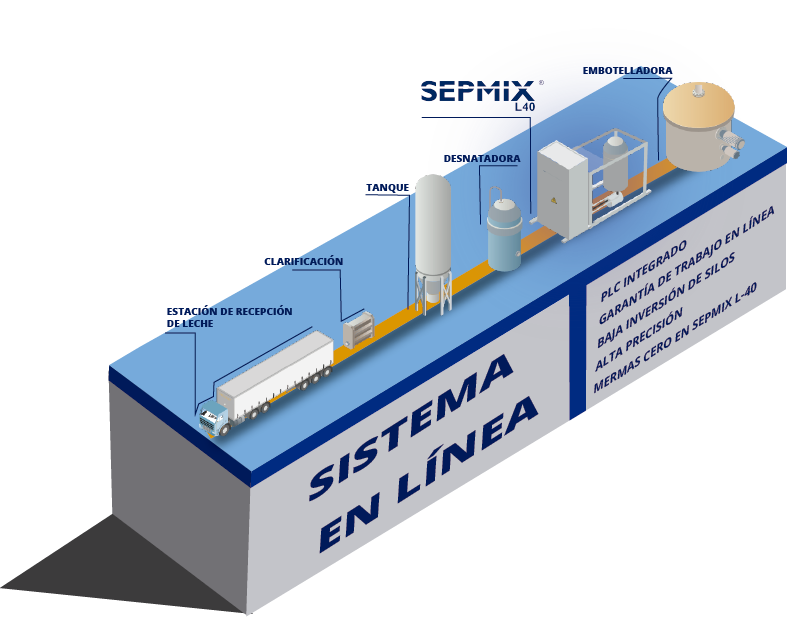

We will present our range of services and products of the highest technology in beverage process engineering.

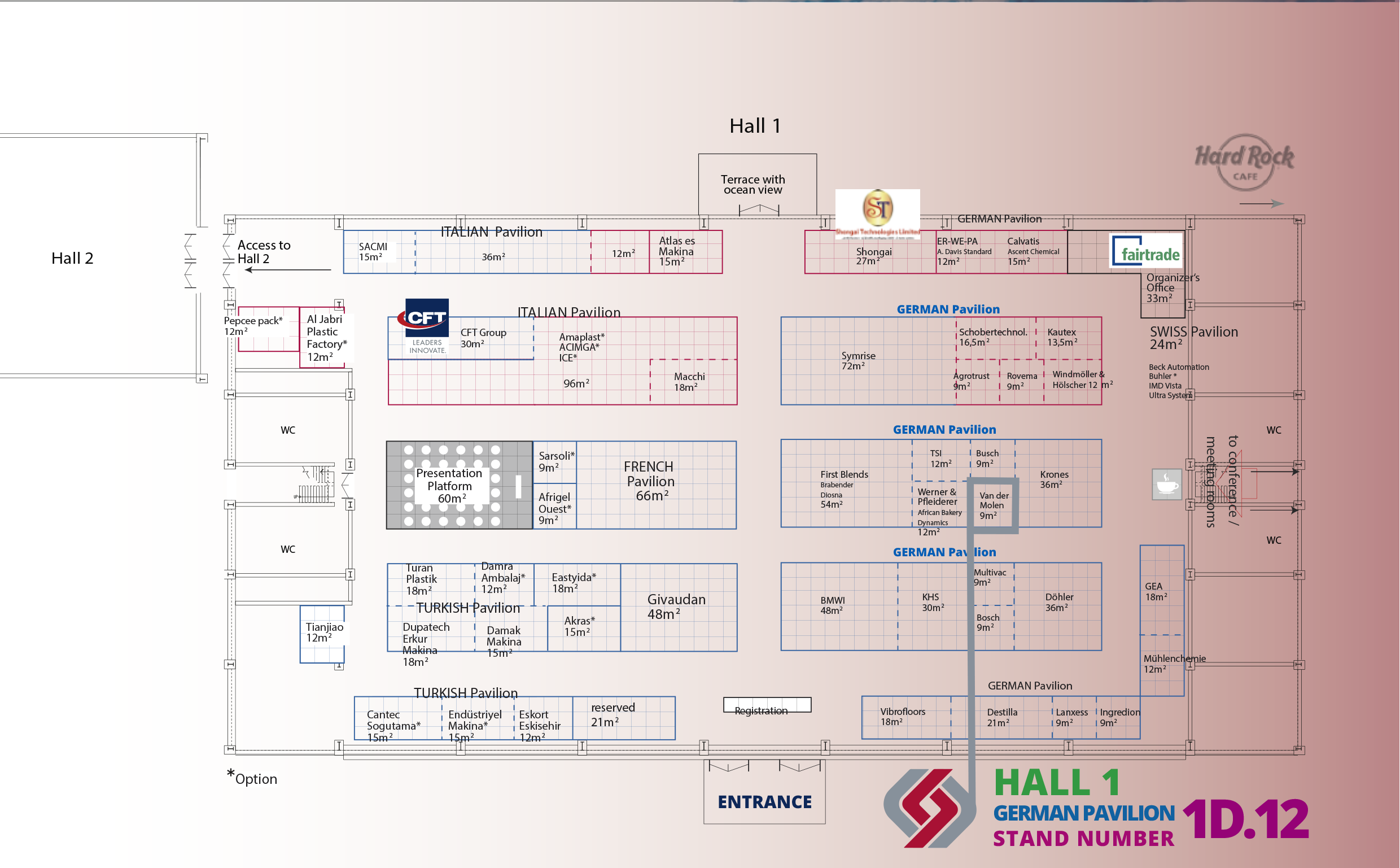

We will be delighted to attend you and show you our news in our Stand 1090, located in Hall 10.

The exhibition schedule will be: Tuesday, 12 to Thursday, 14 December 2019. 10:00 – 18:00.

For more information, please visit the fair website (https://www.drinktechnology-india.com/index.html).